This website uses cookies primarily for visitor analytics. Certain pages will ask you to fill in contact details to receive additional information. On these pages you have the option of having the site log your details for future visits. Indicating you want the site to remember your details will place a cookie on your device. To view our full cookie policy, please click here. You can also view it at any time by going to our Contact Us page.

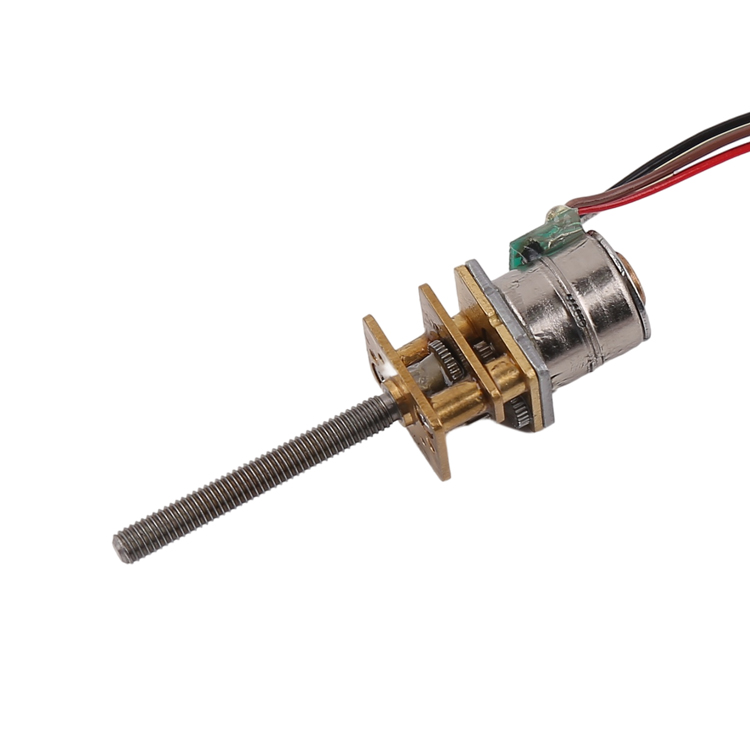

When the operational life exceeds the duration allowable for testing, a systematic approach to reliability demonstration testing (RDT) can provide OEMs with 95 percent certainty that the gearmotors will meet or exceed their required run time. Here, Utpal Rabha, Lead Engineer at Portescap, explains the RDT procedure. DC gearmotors are designed to meet the torque requirements of specific tasks, while ensuring compact dimensions. With an assembly of a brush or brushless DC motor, the device combines a gearbox that optimises torque, speed and efficiency requirements. This enables a gearmotor to reduce output speed, while increasing torque to the required level, achieving this with a more compact diameter compared to using a higher-rated individual motor alone. With the additional gearbox mechanism, it’s imperative that the design of the gearmotor is sufficiently reliable for the duration of its required use. To ensure resilience in real-world conditions, reliability demonstration testing (RDT) is required. Micro Stepper Motor

Read the full article in DPA's April issue

Miniature Dc Motor Print this page | E-mail this page